Smart Manufacturing & ALM for Nordic Industries:

The Future of Digital Factories

Table of Contents

Overview

Smart manufacturing combines automation, data analytics, connectivity, and intelligent systems to optimize production processes. In Nordic countries—leaders in sustainability and innovation—bringing smart manufacturing together with Application Lifecycle Management (ALM) aligns product development, quality, compliance, and sustainability. This pillar page explores how Nordic enterprises can design digital factories for agility and impact.

What Is Smart Manufacturing?

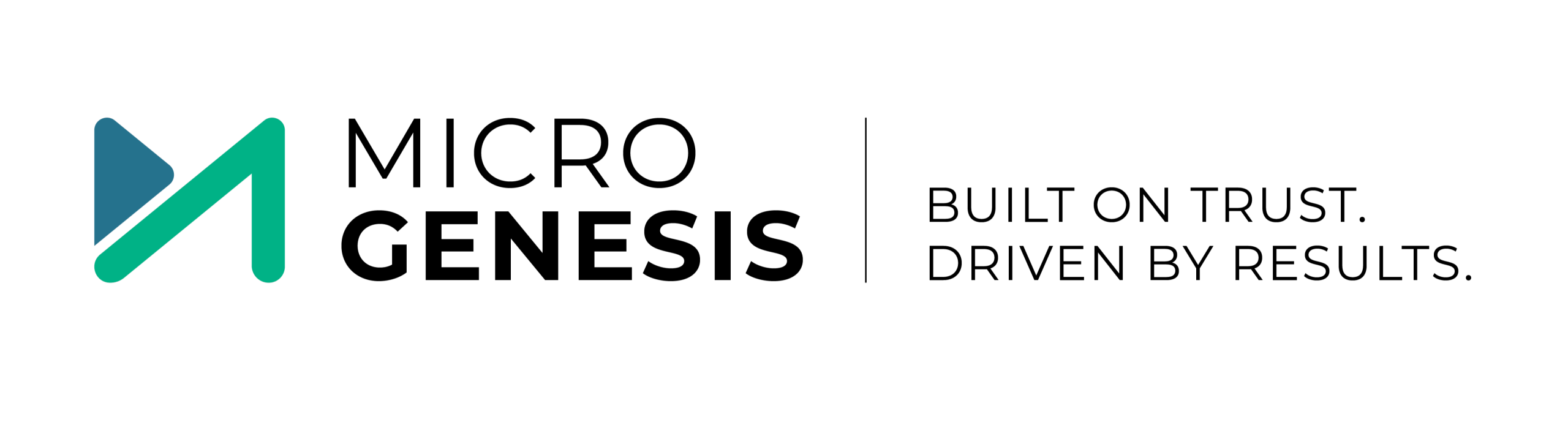

Smart manufacturing uses real-time data and automation to create responsive, efficient, and adaptive production environments. It typically involves:

- Industrial Internet of Things (IIoT) for connectivity

- AI and machine learning for predictive analytics

- Cloud and edge computing for scalable processing

- Digital twins that replicate physical systems

- Cyber-physical systems to self-adjust processes

- Advanced robotics for precision and flexibility

These technologies form an intelligent, transparent production chain that reduces errors and accelerates innovation.

Why Nordic Industries Are Ripe for Smart Transformation

The Nordic region—including Sweden, Finland, Norway, Denmark, and Iceland—has established itself as a global leader in innovation, sustainability, and digital transformation. Its manufacturing sector is especially well-positioned to benefit from the transition to smart manufacturing and Industry 4.0. Here’s a breakdown of the key factors that make Nordic industries uniquely suited for this evolution:

a. Advanced Infrastructure and High Digital Maturity

Nordic countries are among the most digitally advanced in the world. According to the European Commission’s Digital Economy and Society Index (DESI), Finland and Sweden consistently rank among the top performers for connectivity, digital skills, and business digitization.

This digital maturity isn’t limited to consumer sectors—it extends into industry. Many Nordic manufacturers already leverage cloud platforms, advanced analytics, robotics, and AI. Public and private investments have created an environment where 5G networks, edge computing, and digital twin technologies are not futuristic ambitions—they’re operational realities.

This strong foundation makes it easier to adopt smart factory principles such as:

- Real-time production monitoring

- Predictive maintenance

- Connected supply chains

- Automated quality control

b. Strong Focus on Green Energy and Environmental Compliance

Sustainability is more than a goal in the Nordics—it’s embedded in national identity and business strategy. Most of the region’s electricity comes from renewable sources such as hydropower, wind, geothermal, and bioenergy. For example:

- Norway generates over 90% of its electricity from hydropower.

- Denmark is a pioneer in offshore wind energy.

- Finland leads in bioeconomy and circular material flows.

Strict environmental regulations—including carbon taxes, emission limits, and lifecycle directives—push industries to continuously improve efficiency and reduce environmental impact. As a result, Nordic manufacturers are ahead of the curve in:

- Lifecycle assessment (LCA)

- Carbon footprint monitoring

- Sustainable materials usage

- Zero-waste production strategies

Smart manufacturing solutions enable real-time energy tracking, automated emissions reporting, and optimized resource consumption—key tools for staying compliant and competitive in this eco-driven region.

c. Collaborative Innovation Ecosystems

One of the region’s defining strengths is its culture of open innovation and collaboration. Governments actively support innovation through public-private partnerships, R&D grants, and national strategies focused on digital transformation and sustainability.

The industrial landscape thrives on cooperation between:

- Academia – Institutions like VTT (Finland), SINTEF (Norway), and DTU (Denmark) contribute applied research and prototypes.

- Startups – A vibrant ecosystem supports emerging tech in AI, robotics, IoT, and cleantech.

- Large enterprises – Global players like Volvo, Ericsson, ABB, and Nokia invest heavily in digital manufacturing innovation.

- Public sector – Governments play an active role in facilitating technology testbeds, sandboxes, and pilot projects.

This ecosystem creates a fast-track environment for testing, validating, and scaling smart manufacturing technologies—from machine learning algorithms for predictive maintenance to autonomous mobile robots for warehouse optimization.

d. Emphasis on Quality Engineering and High Product Standards

Nordic companies have long been known for producing high-quality, high-reliability products. Whether in automotive safety (Volvo), wireless technology (Nordic Semiconductor), industrial automation (ABB), or precision medical devices, quality is non-negotiable.

This legacy of engineering excellence aligns naturally with smart manufacturing, where:

- Digital threads ensure traceability from design to delivery.

- Digital twins enable proactive testing and simulation.

- Integrated quality systems reduce defects and downtime.

The cultural commitment to precision, durability, and performance drives continuous improvement and accelerates the uptake of technologies that enable high standards at scale.

e. Government Support for Industry 4.0 and Circular Initiatives

Nordic governments are highly progressive in driving digital and sustainable industrial policies. Examples include:

- “Made in Sweden 2030” – Sweden’s strategy for sustainable, digitalized industry.

- Finland’s Circular Economy Roadmap – the first of its kind globally.

- Norway’s Digital21 Plan – guiding digital transformation in all sectors.

- Denmark’s Green Transition Fund – investing in clean energy and smart tech for industry.

Policy incentives, funding schemes, and tax benefits are widely available for projects focused on:

- Automation and robotics

- Digital twins and smart sensors

- Green manufacturing

- Lifecycle assessment (LCA) and reporting tools

- ALM and PLM platform integration

Such strong institutional backing lowers the risk of innovation and empowers businesses to move confidently toward smart transformation.

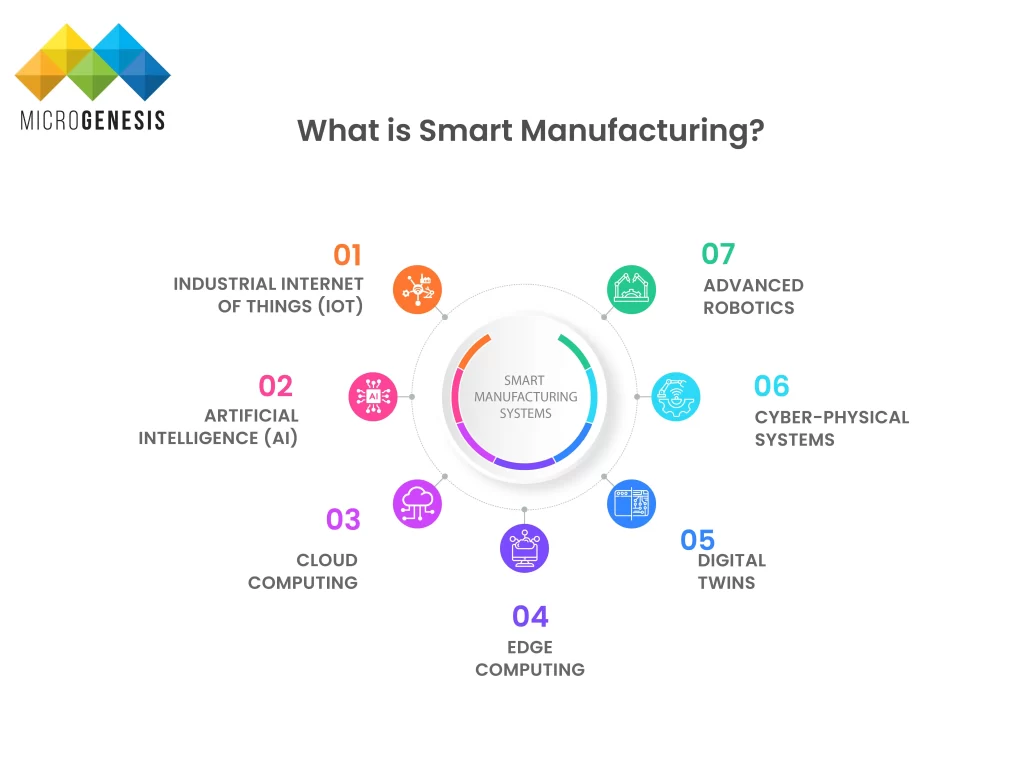

The Role of ALM in Smart Manufacturing

Application Lifecycle Management (ALM) serves as the backbone of smart manufacturing by connecting processes, people, and tools across the entire product lifecycle. In digital factories, where systems are increasingly software-driven and highly regulated, ALM enables seamless coordination and traceability.

Key areas where ALM plays a critical role:

- Product Design and System Modeling

ALM tools help manage evolving requirements and ensure they’re aligned with system models, fostering consistency between product architecture and actual implementation. - Embedded Software Development

Smart products rely heavily on embedded software. ALM supports version control, collaboration, and integration with DevOps pipelines to streamline development and deployment. - Quality Assurance and Test Management

Integrated testing frameworks within ALM ensure early defect detection, automated test execution, and alignment with quality standards throughout the development lifecycle. - Compliance and Sustainability

From ISO standards to green regulations, ALM helps document and track compliance requirements. It supports sustainability goals by integrating lifecycle data, emissions tracking, and circular design checkpoints. - Integration with MES, PLM, and ERP Systems

By bridging Manufacturing Execution Systems (MES), Product Lifecycle Management (PLM), and Enterprise Resource Planning (ERP), ALM enables holistic visibility—from shop floor operations to strategic planning.

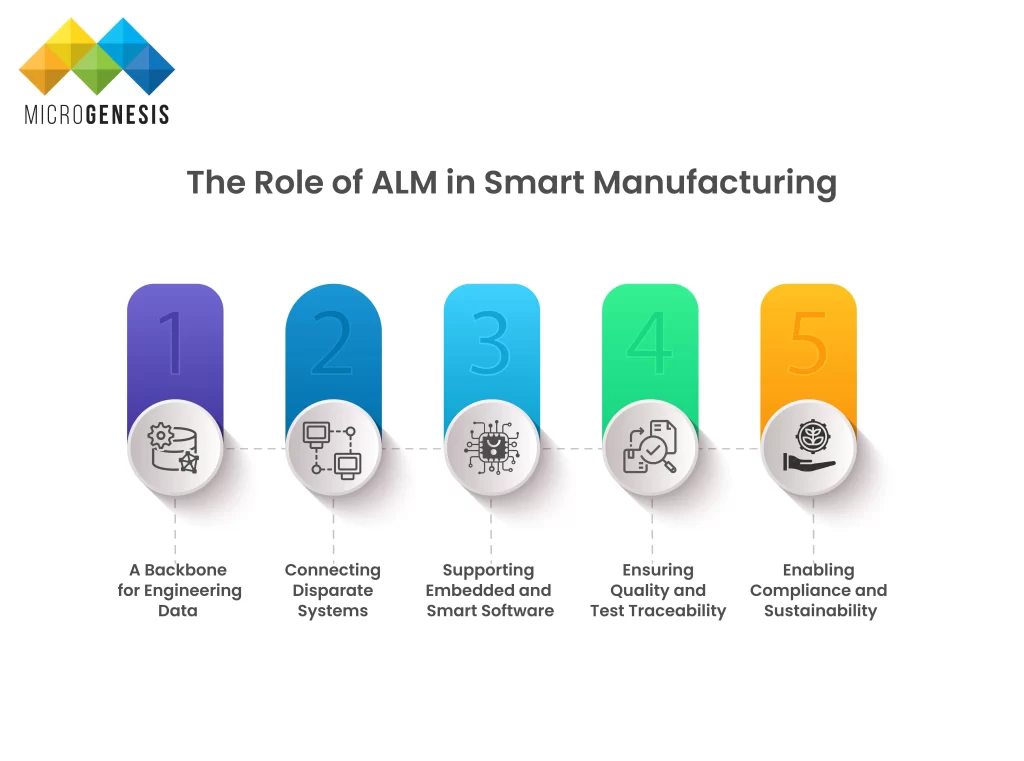

Benefits of Integrating ALM in Digital Factories

- Improved Cross-Disciplinary Collaboration

ALM consolidates mechanical, electrical, and software engineering teams, fostering synchronized workflows.

- Real-Time Traceability and Compliance

Built-in traceability matrices and audit-ready reports automate regulatory, safety, and sustainability compliance.

- Higher Product and Process Quality

Integrated validation reduces defects and machine downtime by catching issues preemptively.

- Faster Time-to-Market

Agile practices and DevOps pipelines supported by ALM accelerate innovation cycles.

- Adaptability to Market Changes

Configurable product variant management (e.g., Pure Variants) supports dynamic production shifts.

- Support for Sustainability Goals

Environmental metrics and recyclability tracking (e.g., Nordic Swan Ecolabel) can be embedded in development workflows

Use Cases for Nordic Sectors

-

- Automotive & eMobility

- Manage embedded software for EVs, autonomous systems, trace requirements to ISO 26262, ASPICE, and ESG targets.

- Industrial Equipment & Robotics

- Use ALM to track variants, predict maintenance needs, and manage real-time IIoT monitoring.

- Aerospace & Defense

- Coordinate supplier networks with DO-178C and ARP 4754 compliance. Digital twins support system-of-systems traceability.

- Medical Devices & Diagnostics

- Link design, risk, and testing for ISO 13485, MDR, FDA. Trace clinical data and ensure validation for patient safety.

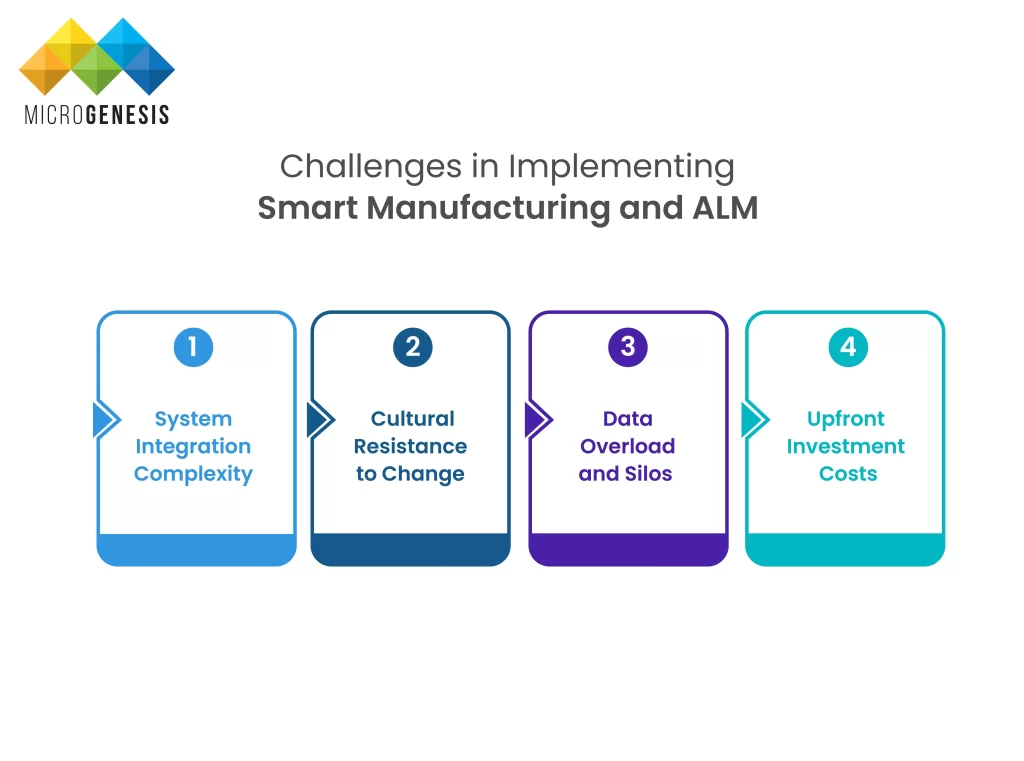

Challenges in Implementing Smart Manufacturing and ALM

While the benefits of smart manufacturing and ALM integration are substantial, the journey to successful implementation is often complex and filled with obstacles. Enterprises—especially those with deep legacy systems or complex operations—must navigate several key challenges.

a. System Integration Complexity

- Many manufacturing organizations still rely on legacy systems such as outdated MES (Manufacturing Execution Systems), PLM (Product Lifecycle Management), or proprietary IoT platforms. These older technologies often lack modern APIs, cloud compatibility, or standardized data formats.

- Integrating such systems with a centralized ALM solution can be resource-intensive and time-consuming. It may require custom connectors, middleware solutions, or even system replacements—raising both technical and operational risks.

- Solution Tip: A phased integration strategy, starting with high-value use cases and pilot lines, can help ease technical barriers while demonstrating early ROI.

b. Cultural Resistance

- Adopting smart manufacturing and ALM often demands a significant shift in mindset. Teams accustomed to siloed or manual workflows may be hesitant to adopt new tools and automated processes, especially if they perceive it as a threat to their roles or autonomy.

- Digital transformation not only changes tools but also redefines collaboration, ownership, and workflows—leading to fear, uncertainty, and resistance if not managed effectively.

- Solution Tip: Strong change management, including leadership buy-in, stakeholder training, and clear communication of benefits, is essential to building adoption and trust.

c. Data Overload and Information Silos

- Smart factories produce massive volumes of real-time data through sensors, connected machines, and software logs. Without effective data governance and integration strategies, this data can quickly become fragmented, inconsistent, or unusable.

- Siloed data impedes real-time decision-making, undermines visibility across departments, and increases the risk of duplicated efforts or missed insights.

- Solution Tip: Implement a centralized data strategy tied to ALM, with emphasis on metadata standards, access control, and clear data ownership across the product lifecycle.

d. Upfront Investment Costs

- Implementing a smart manufacturing ecosystem with ALM involves substantial initial expenditure. Costs may include:

- Upgrading or replacing existing systems

- Licensing new ALM software

- Investing in edge/cloud infrastructure

- Training teams and hiring new talent

- Custom integrations and ongoing maintenance

- While the long-term ROI is typically strong—especially through increased efficiency and reduced downtime—the upfront financial commitment can be a barrier for smaller manufacturers or those with tight margins.

- Solution Tip: Position the investment as part of a broader digital transformation roadmap. Leverage government subsidies (such as Industry 4.0 grants in Nordic countries) and prioritize high-impact areas to generate early success stories.

The Path to Implementation

Successfully implementing Smart Manufacturing supported by ALM (Application Lifecycle Management) requires more than just selecting the right tools. It’s a strategic journey that begins with a clear understanding of business needs and ends with organization-wide adoption, continuous optimization, and measurable outcomes.

Below is a structured roadmap to guide enterprises through this transformation:

a. Assessment and Strategy Development

Before making any technical decisions, it’s essential to perform a comprehensive assessment of current systems and processes.

- Evaluate existing systems: Identify what tools, platforms, and manual processes are currently in place.

- Define objectives: Set clear, measurable goals such as reducing time-to-market, improving compliance, increasing traceability, or optimizing product quality.

- Scope initiatives: Prioritize which product lines, plants, or processes will benefit most from ALM integration.

Outcome: A tailored digital transformation roadmap with defined KPIs and business outcomes.

b. Start with High-Impact Areas

Don’t attempt to implement ALM and smart manufacturing across the entire enterprise at once. Instead, start with pilot programs focused on areas where benefits are most visible.

- Target compliance-heavy lines such as those in automotive or MedTech, where traceability and documentation are mandatory.

- Safety-critical systems or products with strict quality requirements can highlight ALM’s value quickly.

- Choose departments or teams that are open to innovation and willing to experiment.

Outcome: Early wins that build momentum and provide proof of concept for broader rollout.

c. Ensure Cross-Functional Buy-In

Digital transformation is not solely an IT initiative—it touches engineering, operations, quality, compliance, and beyond.

- Involve leadership early: Secure C-suite sponsorship to align on strategic goals and investment.

- Engage cross-functional teams: Include representatives from engineering, quality assurance, product management, and compliance.

- Build a shared language: Encourage collaboration through workshops and stakeholder meetings that clarify roles, expectations, and mutual benefits.

Outcome: Unified commitment and reduced resistance to organizational change.

d. Invest in Integration and Interoperability

Smart manufacturing requires that systems work together seamlessly. Choose ALM tools that are designed to be interoperable with the digital factory ecosystem.

- MES (Manufacturing Execution Systems) for shop-floor integration.

- PLM (Product Lifecycle Management) for engineering design and change management.

- ERP (Enterprise Resource Planning) for financial and resource planning.

- IoT platforms for real-time operational data.

- LCA tools for sustainability tracking and impact modeling.

Outcome: A connected digital thread that spans the full product lifecycle, improving real-time decision-making and data integrity.

e. Train and Upskill Teams

Adopting ALM in smart manufacturing means introducing new workflows, tools, and digital responsibilities.

- Upskill engineering and IT teams in ALM architecture, digital thread strategies, and tool administration.

- Offer role-specific training for product managers, QA, compliance officers, and operations staff.

- Encourage ongoing learning through certifications, hands-on labs, and partnerships with technology vendors or academic institutions.

Outcome: A digitally fluent workforce ready to sustain and scale smart manufacturing initiatives.

Future Outlook for Nordic Digital Factories

- Nordic industries are uniquely positioned to lead the next wave of manufacturing innovation, where sustainability, data-driven operations, and advanced automation converge. As digitalization accelerates and environmental imperatives deepen, the Nordic region is set to transform from early adopters to global trendsetters in smart manufacturing.

- Below are the key trends shaping the future of Nordic digital factories:

a. AI-Augmented Engineering & Autonomous Systems

- Nordic manufacturing will increasingly harness artificial intelligence (AI) to enhance decision-making, reduce defects, and improve production efficiency.

- Self-optimizing machines: Systems will learn from real-time sensor data to adjust parameters, reduce energy consumption, and improve quality autonomously.

- Predictive quality assurance: AI algorithms will detect production anomalies before they escalate, enabling proactive interventions.

- Cognitive automation: AI will assist engineers in simulation, design validation, and complex system integration—reducing development cycles.

- These intelligent systems reduce downtime, improve resource utilization, and lower operational costs, aligning with both productivity and sustainability goals.

b. Decentralized, Cloud-Based Manufacturing

- The cloud is transforming manufacturing into a globally synchronized, data-driven enterprise.

- Real-time ALM synchronization: Factories across regions can operate using a unified application lifecycle system, keeping engineering, operations, and quality aligned.

- Remote collaboration: Cross-border teams in Denmark, Sweden, and Finland can co-develop and co-maintain smart products in real time.

- Edge-cloud integration: Critical factory decisions can be made at the edge while syncing with enterprise platforms in the cloud for global insights.

- This distributed model enhances business continuity, speeds up innovation, and reduces dependency on centralized infrastructure.

c. ESG-Centric Product Development

- Environmental, Social, and Governance (ESG) performance is moving from optional to mandatory—and digital factories are integrating ESG goals into core engineering practices.

- Lifecycle impact modeling: Every decision—from material selection to manufacturing process—will be modeled and evaluated for CO₂ impact, recyclability, and compliance.

- Real-time sustainability dashboards: Factories will have visibility into energy use, waste generation, and carbon emissions at every product lifecycle stage.

- Digital compliance alignment: Continuous updates on environmental regulations (like EU Taxonomy or CSRD) will be embedded directly into engineering workflows.

- By embedding ESG into ALM and product development, Nordic enterprises ensure compliance, attract ethical investment, and respond to growing consumer expectations.

d. Collaborative Digital Twin Ecosystems

- The future factory won’t operate in isolation—collaboration will extend across supply chains via digital twin technology.

- Live digital twins shared across OEMs and suppliers: These virtual models will mirror physical production and product behavior in real time, enabling faster problem resolution and joint development.

- Multi-enterprise simulation environments: From Tier 1 suppliers to logistics providers, all stakeholders can run scenario planning to optimize resource usage and reduce risk.

- Unified compliance and traceability: Digital twins will embed traceability data—components, certifications, supplier origin—into a shared, accessible format for regulatory audits or sustainability disclosures.

- This ecosystem approach unlocks new levels of agility, risk management, and co-innovation, essential for complex and regulated industries like automotive, medical devices, and electronics.

Conclusion

Smart manufacturing, when combined with ALM, positions Nordic enterprises to lead in sustainability, innovation, and competitiveness. By integrating ALM across digital factories, companies gain traceable, compliant, and efficient systems that adapt and scale with purpose. The Nordics are setting a global benchmark—building resilient, connected, and responsible production ecosystems.