AI in Product Engineering & ALM:

A Complete Guide for Nordic Enterprises

Table of Contents

Overview

Smart manufacturing combines automation, data analytics, connectivity, and intelligent systems to optimize production processes. In Nordic countries—leaders in sustainability and innovation—bringing smart manufacturing together with Application Lifecycle Management (ALM) aligns product development, quality, compliance, and sustainability. This pillar page explores how Nordic enterprises can design digital factories for agility and impact.

What is AI in Product Engineering & ALM

AI in Product Engineering uses artificial intelligence—including machine learning, predictive analytics, and automation—to optimize how teams plan, design, build, test, and deliver products.

ALM, or Application Lifecycle Management, refers to the structured process of managing a product’s entire lifecycle. AI transforms ALM into a more intelligent, automated, and efficient practice by offering:

a.Predictive analytics

b. Workflow automation

c. Real-time traceability

d. Smart decision support

Why AI is Crucial for Nordic Enterprises

Nordic countries—Sweden, Norway, Denmark, and Finland—have built strong reputations as global leaders in technological innovation, environmental responsibility, and high-quality engineering standards. As global markets evolve rapidly and sustainability becomes central to every enterprise strategy, AI provides Nordic organizations with the competitive edge they need to thrive and lead.

Adopting AI is not just about keeping pace with technology trends—it is about reinforcing the region’s core values of efficiency, accountability, and continuous improvement. Here’s how AI contributes to those goals:

a. Improving Development Efficiency and Speed

AI enables teams to automate time-consuming, repetitive tasks across the product lifecycle—such as test case generation, requirement tracking, risk analysis, and documentation. This results in faster cycles from design to deployment.

- AI-enhanced platforms optimize development workflows, minimize manual errors, and accelerate iteration.

- Predictive models can anticipate resource bottlenecks, recommend solutions, and help teams prioritize tasks effectively.

- AI supports agile and DevOps methodologies by aligning planning, execution, and validation in real time.

For Nordic enterprises with strong R&D cultures, this efficiency translates to shorter time-to-market, improved ROI, and more time for innovation.

b. Reducing Environmental Impact Through Optimization

Sustainability is embedded in Nordic values and policy. AI contributes to this by enabling smarter product design and energy-efficient operations.

- AI simulations help reduce material waste by predicting design flaws and improving system performance before physical prototyping.

- Lifecycle optimization powered by AI can reduce overproduction, unnecessary transportation, and excessive energy use.

- AI-driven supply chain visibility supports eco-conscious sourcing and production planning.

For Nordic companies focused on environmental leadership, AI strengthens ESG strategies and enhances compliance with evolving EU Green Deal targets and national sustainability frameworks.

c. Enhancing Traceability and Compliance in Regulated Industries

The Nordic region is home to major players in aerospace, medical devices, automotive, and clean tech—industries where regulatory compliance is non-negotiable.

AI supports traceability and quality assurance by:

- Maintaining automated, auditable trails from requirements through to validation

- Ensuring consistent alignment with standards like ISO 13485, ISO 26262, DO-178C, and GDPR

- Reducing compliance risk by highlighting anomalies, gaps, or non-conformances before audits

With AI, compliance becomes a built-in, real-time process rather than a costly, reactive task.

d. Helping Teams Innovate at Scale and Compete Globally

AI allows companies to scale operations intelligently without proportionally increasing complexity or overhead.

- Teams across locations can collaborate on shared AI-enhanced platforms that unify data, workflows, and communication.

- Advanced analytics allow R&D units to predict market trends, user behaviors, and product performance with greater accuracy.

- AI helps Nordic firms remain competitive internationally by fostering continuous innovation, even in complex, multi-product environments.

By enabling smarter, faster, and more collaborative product development, AI empowers Nordic enterprises to uphold their reputation for excellence and lead global transformation in sustainable engineering and digital innovation.

Key Benefits of AI in Engineering

Artificial Intelligence is fundamentally transforming the way engineering teams design, develop, test, and maintain products. For organizations across the Nordics and beyond, the integration of AI into engineering processes offers significant advantages that support innovation, efficiency, compliance, and collaboration. Below are the key benefits explained in greater depth:

1. Improved Efficiency

AI streamlines and automates time-consuming, manual tasks such as data entry, document creation, defect logging, test case execution, and report generation.

- Engineering teams can reallocate time from routine work to strategic innovation and problem-solving.

- Intelligent automation improves process consistency and reduces the likelihood of human error.

- Engineers can access AI-driven assistants that help write code, check syntax, and validate architectural decisions.

The result is faster workflows and reduced operational overhead, allowing companies to develop complex systems with leaner teams and tighter timelines.

2. Faster Time to Market

AI plays a pivotal role in accelerating development cycles and shortening product delivery timelines.

- Predictive analytics identify potential risks, dependencies, and resource gaps early in the development phase.

- AI tools help optimize sprint planning, backlog grooming, and release schedules by analyzing historical data and performance metrics.

- Automated testing and continuous integration pipelines allow for quicker iterations and faster feedback loops.

For competitive industries and fast-moving markets, AI enables organizations to deliver new features, products, and updates with greater speed and confidence.

3. Enhanced Product Quality

AI improves the overall quality and reliability of products by enhancing the way testing and validation are carried out.

- Machine learning models can detect patterns in bugs and defects, allowing teams to predict high-risk areas in new code.

- AI helps prioritize test cases based on risk levels and historical failure rates, ensuring that critical functions are tested thoroughly.

- Intelligent anomaly detection tools monitor real-time system behavior, flagging unusual or unexpected performance early.

By catching issues earlier in the lifecycle and improving test accuracy, AI reduces production defects and increases end-user satisfaction.

4. Better Decision Making

AI provides actionable insights that help teams make more informed and strategic decisions across the engineering lifecycle.

- Dashboards powered by AI aggregate data from various sources—requirements, issues, testing, usage patterns—and present it in context.

- Teams gain visibility into performance trends, resource allocation, bottlenecks, and customer impact.

- AI can simulate multiple development or release scenarios, enabling leadership to select the optimal path forward based on risk and ROI.

With better data and automated analysis, decision-making becomes faster, more consistent, and less subjective.

5. Easier Compliance

AI supports continuous compliance with regulatory standards by embedding traceability and documentation directly into engineering workflows.

- AI tools automatically track changes across requirements, design, code, and tests, generating audit trails in real-time.

- Document templates and validation protocols ensure that deliverables meet industry-specific regulations like ISO, IEC, DO-178C, or ISO 13485.

- AI can flag missing links between requirements and verification artifacts, reducing gaps that often lead to audit failures.

This shift from manual to intelligent compliance helps teams avoid costly delays and penalties while ensuring product safety and market readiness.

6. Stronger Collaboration

AI enhances cross-functional collaboration by centralizing data and improving visibility for all stakeholders.

- Engineering, QA, product, and compliance teams can access shared dashboards, intelligent workflows, and real-time updates.

- Natural Language Processing (NLP) capabilities enable easier access to project data using intuitive queries (e.g., “Show untested safety requirements”).

- AI-powered assistants can summarize meeting notes, highlight project blockers, or send intelligent reminders—keeping everyone aligned.

As a result, teams work more cohesively, communication improves, and knowledge is preserved across projects and departments.

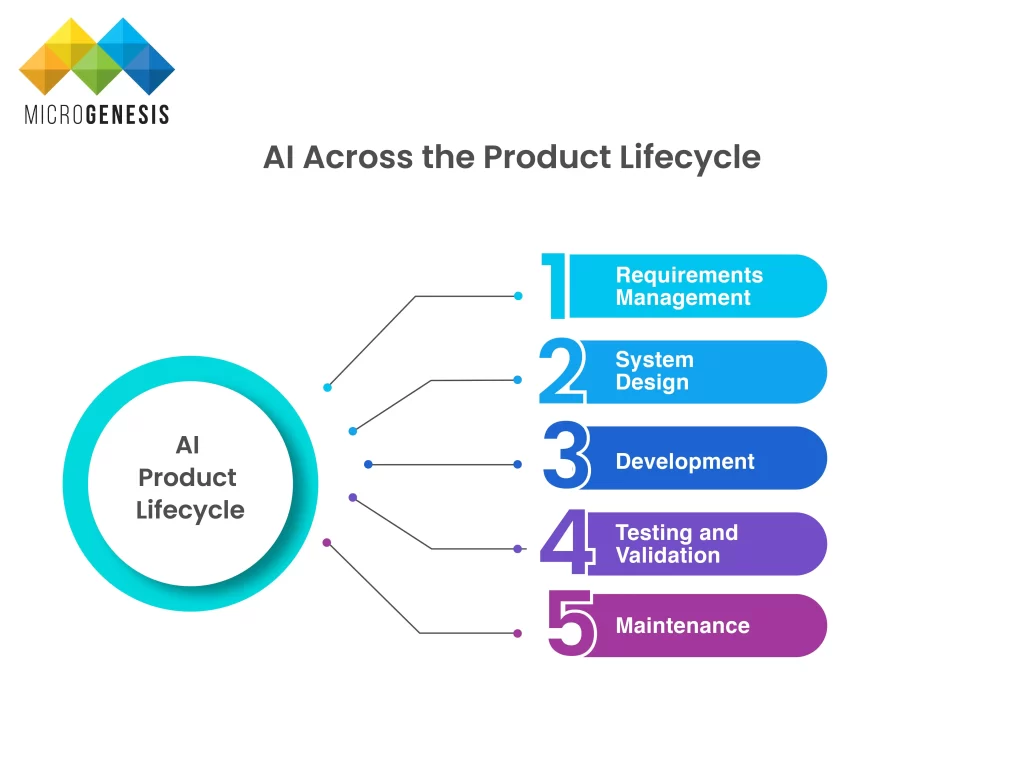

AI Across the Product Lifecycle

AI plays a critical role at every stage of the product lifecycle, offering opportunities for automation, risk reduction, and enhanced innovation. From initial planning through post-release maintenance, AI transforms traditional engineering workflows into intelligent, data-driven processes that improve speed, quality, and collaboration.

a. Requirements Management

AI enhances the quality and clarity of requirements by interpreting natural language inputs from stakeholders, converting them into structured, testable formats.

- Natural Language Processing (NLP) tools extract functional and non-functional requirements from documents, emails, and meetings.

- AI can identify ambiguities, duplicates, or inconsistencies in requirements to reduce rework later in development.

- Automated traceability links requirements directly to design models, test cases, and validation results.

This ensures clear, actionable inputs from the beginning, minimizing misunderstandings and missed expectations.

b. System Design

During the system design phase, AI supports teams in building models that are optimized for performance, reliability, and cost.

- AI-based modeling tools simulate component interactions, validate architecture choices, and predict system behavior.

- Design decisions can be validated against historical data, ensuring that selected configurations are both feasible and efficient.

- AI can recommend design alternatives based on previous project outcomes or performance benchmarks.

This leads to smarter, faster decisions and reduces design flaws that might otherwise only be detected later.

c. Development

AI improves software development through intelligent coding assistance and real-time feedback.

- Code completion tools powered by machine learning help developers write cleaner, more efficient code.

- AI can detect code smells, redundant logic, or security vulnerabilities before they’re committed.

- Predictive analytics highlight risky modules or files based on commit history, test failures, and user-reported bugs.

By improving code quality at the source, AI reduces technical debt and improves maintainability.

d. Testing and Validation

AI revolutionizes testing by automating test generation, prioritizing tests based on impact, and increasing overall coverage.

- Test case generation tools use historical data, code analysis, and usage patterns to suggest relevant test scenarios.

- Risk-based testing prioritizes areas most likely to fail, optimizing test efforts and resource allocation.

- AI continuously learns from test outcomes to improve future testing strategies and reduce false positives/negatives.

This ensures that testing becomes a continuous, adaptive process rather than a bottleneck.

e. Maintenance

Once a product is released, AI continues to deliver value by monitoring performance and identifying potential issues.

- AI-powered monitoring tools collect telemetry data and analyze it in real-time to detect anomalies or deviations from expected behavior.

- Predictive maintenance models forecast component failure based on usage patterns, reducing downtime and maintenance costs.

- AI can recommend proactive updates or adjustments based on how users interact with the system.

This enables organizations to maintain reliability, improve customer satisfaction, and extend product lifecycle value.

The Role of NLP in Engineering

Natural Language Processing (NLP) is a subfield of artificial intelligence that enables machines to read, understand, and derive meaning from human language. In the context of engineering and product lifecycle management, NLP acts as a critical bridge between human communication and structured system data.

Modern engineering environments rely heavily on documentation, specifications, user feedback, compliance reports, and other unstructured text-based resources. NLP transforms these documents into actionable insights, enabling engineering teams to improve productivity, accuracy, and compliance—especially in complex, highly regulated industries.

a. Automated Requirements Extraction from Technical Documents

One of the most powerful applications of NLP in engineering is its ability to extract clear, structured requirements from unstructured content such as emails, meeting notes, stakeholder feedback, or regulatory guidelines.

- NLP tools scan documents to identify and isolate requirement statements, classifying them by priority, type, or relevance.

- The system highlights vague or ambiguous language and suggests improvements based on past projects or templates.

- Extracted requirements can be directly imported into ALM tools, reducing manual effort and the risk of missing critical inputs.

This not only accelerates early-phase engineering but also ensures that all team members are working from the same, clearly defined foundation.

b. Traceability Mapping Across Requirements, Test Cases, and Defects

NLP helps maintain full traceability between artifacts throughout the development process by automatically identifying and linking related items across documentation and system records.

- The system can recognize references between requirements and test plans, or between bug reports and design components.

- Even when different teams use varying language or naming conventions, NLP can identify the semantic relationships between them.

- This supports compliance with industry regulations and internal standards by maintaining a live traceability matrix that is continuously updated.

For engineering teams working with evolving or legacy documentation, NLP simplifies change impact analysis and reduces manual overhead.

c. Natural-Language Search Within Project Repositories

Instead of memorizing specific fields, keywords, or query syntax, engineers and managers can use plain language to search through complex project data.

- Queries such as “Show me all unresolved security issues related to login” or “Find requirements related to ISO 13485” yield intelligent, context-aware results.

- NLP understands the intent behind the query, retrieves relevant artifacts, and ranks them by relevance and recency.

- This capability makes historical knowledge more accessible, reduces reliance on tribal knowledge, and improves onboarding for new team members.

This kind of intuitive search experience increases productivity and encourages better use of historical data.

d. Regulatory Compliance Alignment Through Document Scanning

Regulated industries such as aerospace, automotive, and medical devices must align product development with strict standards. NLP supports this by scanning regulations and mapping them to corresponding engineering artifacts.

- NLP tools parse standards documents, highlight applicable sections, and recommend links to internal documents or test results.

- They identify compliance gaps where requirements or validations are missing or insufficient.

- Automated reports are generated to support audit preparation, reducing the stress and time traditionally involved.

For Nordic enterprises subject to EU regulations and international frameworks, this capability is essential for demonstrating due diligence and maintaining certification.

e. Executive Summaries and Reporting Generated from Long Texts

NLP can automatically summarize long documents, emails, meeting transcripts, or project updates, generating clear and concise summaries for various stakeholders.

- Engineering managers can receive weekly project snapshots that consolidate technical data into business-ready summaries.

- Stakeholders get digestible reports outlining risk status, compliance coverage, or open issues without manually reading through all details.

- The summaries can be customized based on audience—technical, managerial, or regulatory.

This saves time, improves communication across departments, and ensures that decisions are made based on accurate, up-to-date information.

NLP’s Strategic Relevance in Nordic Enterprises

Nordic teams often operate in multilingual environments with stakeholders distributed across multiple countries. Moreover, many enterprises must comply with industry-specific regulations while maintaining documentation in English, Swedish, Finnish, Danish, or Norwegian.

In these contexts, NLP provides tremendous value by:

- Standardizing terminology across teams and projects

- Supporting translation and localization efforts for multi-country deployments

- Reducing human error in documentation and data entry

- Helping non-technical stakeholders engage with technical projects through plain-language reports

By turning unstructured content into a strategic asset, NLP supports clarity, consistency, and speed—making it an indispensable component of AI-enabled engineering in the Nordics.

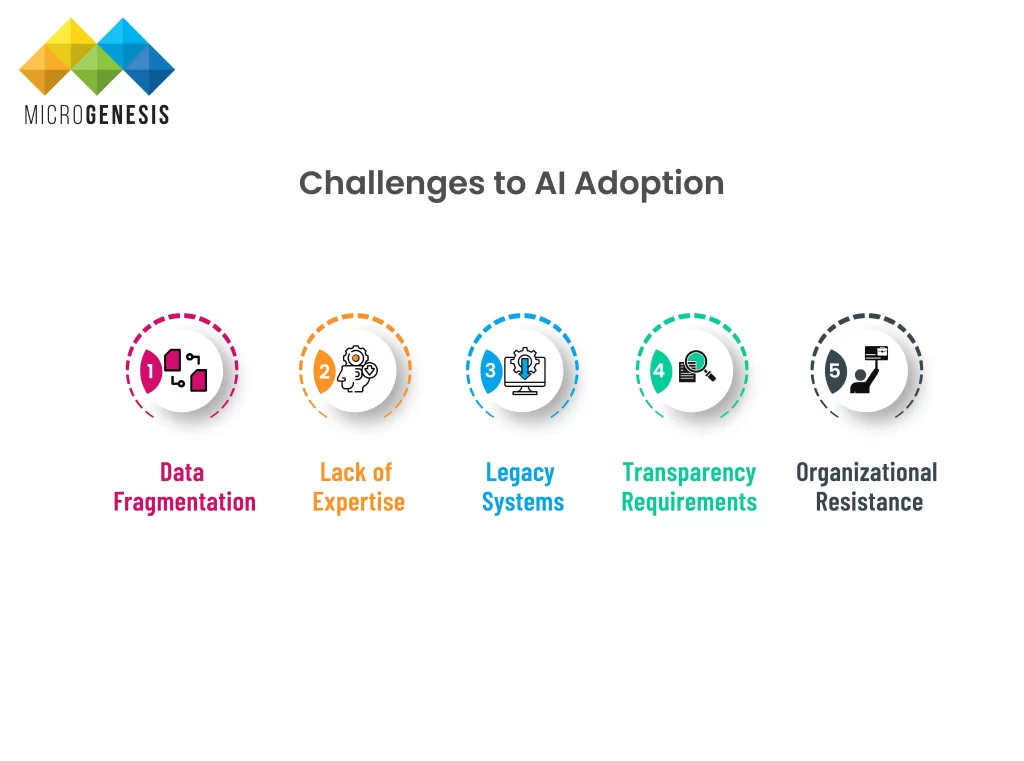

Challenges to AI Adoption

While AI offers significant advantages to engineering and product lifecycle management, its adoption is not without obstacles. Organizations—especially those in highly regulated or traditionally structured industries—often encounter practical and cultural barriers when introducing AI technologies. Understanding these challenges is the first step toward overcoming them.

1. Data Fragmentation

AI systems rely heavily on access to clean, integrated, and well-structured data. However, many organizations still operate in silos, with engineering, testing, compliance, and quality data spread across disconnected systems.

- Data may exist in various formats (spreadsheets, PDFs, emails, legacy systems), making it difficult for AI tools to ingest and learn from them.

- Inconsistent naming conventions and lack of metadata further reduce the value of historical data.

- Without unified data architecture, AI outputs can become incomplete or misleading.

Solution: Establish a centralized data governance framework. Invest in data integration tools or platforms that consolidate cross-departmental data into accessible formats with consistent structure.

2. Lack of Expertise

Despite the growing popularity of AI, many engineering teams have limited experience working with machine learning models, natural language processing, or automation workflows.

- Engineers may lack the knowledge to evaluate AI tools or interpret AI-generated insights effectively.

- Product managers and team leads may be uncertain about where to apply AI for maximum ROI.

- Organizations may not have dedicated data science or AI engineering teams to support adoption.

Solution: Provide targeted training programs, create cross-functional AI task forces, and consider hiring or consulting with AI specialists to guide implementation and ensure knowledge transfer.

3. Legacy Systems

Older IT and development infrastructures are often incompatible with modern AI platforms and cloud-based AI tools.

- Legacy ALM, PLM, or ERP systems may not support APIs, real-time data sharing, or flexible integration models.

- On-premise setups can limit access to scalable computing power, which is essential for machine learning.

- Data trapped in outdated systems may be difficult to extract and convert into formats usable by AI.

Solution: Begin modernizing infrastructure in phases—starting with high-impact areas like requirement tracking or testing. Use pilot projects to demonstrate value and justify further investment in modernization.

4. Transparency Requirements

For industries governed by regulatory frameworks, black-box AI models that cannot explain how they arrived at a decision pose compliance risks.

- Safety-critical industries like aerospace, automotive, and healthcare require full traceability and explainability.

- If AI-driven tools cannot justify a decision or provide clear audit trails, they may be rejected by auditors or regulators.

- Unclear models can also erode trust within teams and slow down adoption.

Solution: Use explainable AI (XAI) models wherever possible. Ensure tools log every recommendation, include supporting evidence, and align with compliance documentation needs.

5. Organizational Resistance

Even when the technology is ready, people might not be. Cultural resistance to change can hinder AI initiatives more than technical limitations.

- Employees may fear job loss due to automation or mistrust AI recommendations.

- Managers may hesitate to adopt new tools that challenge familiar workflows or require retraining.

- Without visible leadership support, AI initiatives may stall or face passive resistance.

Solution: Build a change management plan that includes stakeholder engagement, clear communication of benefits, phased rollouts, and incentives for adoption. Highlight successful use cases and foster a culture of experimentation.

Practical Solutions to Overcome AI Adoption Barriers

To address these challenges, organizations can take a structured, phased approach:

- Cross-functional training: Empower engineering, quality, and compliance teams to work with AI tools confidently.

- Platform modernization: Invest in systems that support flexible integration, real-time data exchange, and scalable AI workloads.

- Pilot programs: Start small with AI projects in specific areas (e.g., test automation, documentation generation) and scale based on success.

- Data governance planning: Clean, structure, and unify your data assets before launching AI models to ensure high-quality outputs and insights.

By addressing both technical and human factors, Nordic enterprises can build a sustainable foundation for AI adoption—positioning themselves to lead innovation while managing risk effectively.

Compliance & Regulation in the Nordics

AI adoption must align with regional and global compliance standards, including:

- GDPR – Data privacy and protection

b. EU AI Act – Classifying AI systems by risk

c. ISO 26262 – Automotive functional safety

d. ISO 13485 – Medical device development

e. DO-178C – Aerospace software lifecycle

f. National ESG mandates – Environmental and sustainability reporting

Nordic enterprises should use AI systems that are:

- Explainable and auditable

- Secure and GDPR-compliant

- Traceable from requirement to release

Future Trends in AI-Driven Product Engineering

- Explainable AI (XAI)

Transparent models that clarify how decisions are made. - Digital Twins

Real-time simulation of products to monitor and improve performance. - Federated Learning

Training AI models across decentralized data sets without moving sensitive data. - Sustainability AI

Tools that optimize material usage and reduce carbon emissions. - Generative AI

Creation of test cases, user stories, and documentation using natural language prompts.

Preparing Your Organization for AI

Step 1: Evaluate Readiness

Audit current tools, data, and skill levels.

Step 2: Create a Strategic Roadmap

Identify business goals and prioritize high-value AI use cases.

Step 3: Upskill Teams

Train staff on AI technologies and compliance requirements.

Step 4: Pilot and Scale

Launch small AI initiatives, measure outcomes, and expand successful ones.

Step 5: Establish Governance

Define processes for data privacy, ethical use, and model performance monitoring.

Conclusion

AI is reshaping the future of engineering. For Nordic enterprises, it offers a pathway to smarter workflows, better products, and global leadership in innovation. By integrating AI into product engineering and ALM, companies can accelerate delivery, improve compliance, and strengthen sustainability outcomes.

With the right strategy, AI becomes not just a tool—but a transformation driver.