Digital Twin in Product Development:

A Practical Guide for Automotive & MedTech

Table of Contents

Overview

In today’s innovation-driven industries, digital twin technology has become a cornerstone of smart product development. As manufacturers face growing demands for efficiency, regulatory compliance, and product performance, digital twins offer a powerful way to simulate, analyze, and optimize complex systems—before they are physically built.

In both the automotive industry and MedTech product development, digital twins are reshaping how engineers and organizations approach risk, quality, and lifecycle performance. This practical guide explores how digital twin applications are helping these sectors improve speed, safety, and scalability through virtual modeling and real-time feedback.

What Is a Digital Twin?

A digital twin is a dynamic, real-time digital representation of a physical product, process, or system. It integrates data from design files, sensors, user behavior, and field conditions to create a living simulation. Digital twins are commonly used in industries such as automotive, aerospace, and healthcare, and they are rapidly being adopted across regulated sectors like medical devices.

More than a static 3D model, a digital twin in product development evolves with the physical product, enabling continuous validation and optimization. It’s especially effective when paired with simulation modeling, predictive analytics, and Application Lifecycle Management (ALM).

Why Digital Twins Matter in Automotive and MedTech

In industries where safety, precision, and regulation are paramount, digital twin applications in healthcare and automotive are game changers. Both sectors rely on complex systems that require full traceability, long lifecycle support, and continuous testing.

Automotive Industry:

- Digital twins enable automotive product development tools to simulate vehicle dynamics, emissions, and safety systems in virtual environments.

- They support validation under ISO 26262 and help comply with ASPICE standards for software and system engineering.

Medical Devices:

- A digital twin in MedTech can model how an implant or diagnostic device interacts with human physiology, enabling early risk detection.

- It ensures compliance with ISO 13485, FDA 21 CFR Part 820, and the EU MDR by documenting virtual design controls and patient outcomes.

Key Benefits of Digital Twin Technology

a. Faster Product Development

Using a digital twin in automotive or MedTech eliminates the need for excessive prototypes. Engineers can identify design flaws early and accelerate validation cycles.

b. Improved Quality and Reliability

Digital twins simulate real-world usage, improving product quality and reducing defects. In the medical field, this enhances patient safety.

c. Lifecycle Performance Tracking

Through real-time data, digital twins monitor product health post-deployment—key for predictive maintenance in vehicles and remote monitoring in medical devices.

d. Enhanced Collaboration

Cross-functional teams use a shared digital environment to collaborate effectively across geographies and disciplines.

e. Regulatory Compliance and Risk Management

With digital twin for regulatory compliance, manufacturers can map every design decision, proving adherence to quality standards during audits.

How Digital Twins Support Product Lifecycle Management

The integration of digital twin technology with Product Lifecycle Management (PLM) and Application Lifecycle Management (ALM) systems allows manufacturers to create a seamless, data-driven environment that supports every phase of a product’s lifecycle. This approach not only improves operational efficiency but also enhances traceability, compliance, and sustainability across development cycles.

Below is a breakdown of how digital twins enable a smarter, more connected product lifecycle:

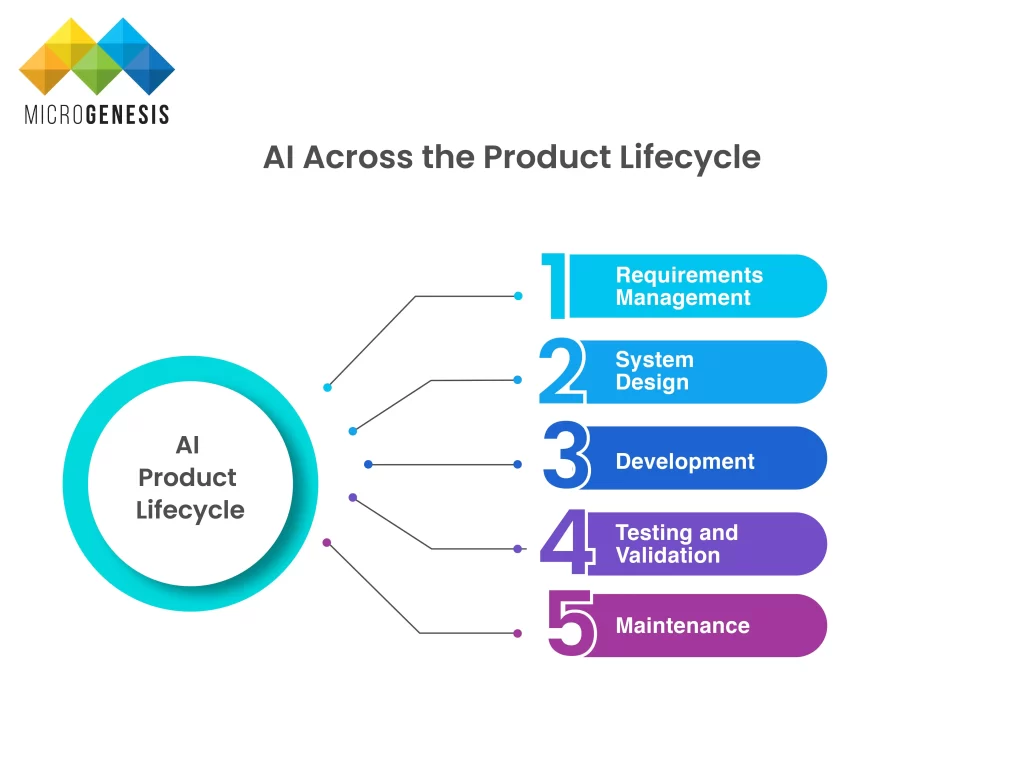

1. Design

In the early stages of product development, digital twins are connected to Computer-Aided Design (CAD) tools and simulation software. This integration allows engineers to:

- Virtually test product geometry, stress limits, and thermal behavior

- Optimize component layouts and materials without physical prototypes

- Run multi-physics simulations to predict how products will behave in real-world environments

With early validation through simulation modeling, teams reduce design iterations and accelerate concept-to-prototype timelines.

2. Development

During the development phase, digital twins synchronize with ALM software to manage evolving software requirements, hardware specifications, and control systems.

- Software and hardware are co-developed with synchronized version control

- Digital twins simulate embedded systems and control logic in real-time

- Defect tracking, code validation, and functional safety tests are linked directly to the twin

This ensures real-time collaboration between cross-functional teams and maintains traceability from initial requirements to finished components.

3. Testing

Testing is where digital twins truly shine. By using live and historical data from real-world conditions, teams can:

- Automatically generate test cases that reflect actual usage scenarios

- Validate safety and performance under varying loads, temperatures, and environments

- Identify potential failure modes and correct them before production begins

Digital twins also support continuous testing as part of agile and DevOps workflows, enabling faster feedback loops and higher product quality.

4. Operation

Once a product is in the field, the digital twin serves as a digital mirror of its real-world counterpart.

- Data from IoT sensors is streamed into the twin for real-time monitoring

- Engineers analyze performance trends, usage behavior, and operational anomalies

- AI algorithms within the twin can suggest updates or predict failures

This leads to predictive maintenance, extended uptime, and data-driven product improvements—all without disrupting service or customer experience.

5. End-of-Life

At the end of a product’s lifecycle, digital twins contribute to sustainable manufacturing and circular economy practices by:

- Tracking material composition and recyclability of each component

- Logging service history and usage metrics for reuse or refurbishment planning

- Supporting environmental impact assessments and regulatory reporting

This level of transparency supports eco-conscious product design, reduces waste, and enables manufacturers to meet growing demands for ESG reporting.

Conclusion: Lifecycle Synergy Through Digital Twins

By bridging the gap between design, development, testing, operation, and end-of-life processes, digital twins ensure continuity, visibility, and control. When paired with robust ALM in manufacturing environments and modern PLM systems, digital twins enable:

- Real-time decision-making

- Compliance with regulatory and safety standards

- Greater responsiveness to market and environmental changes

- Cost savings through design reuse and maintenance optimization

Ultimately, digital twins are not just tools for product simulation—they are strategic assets for driving innovation and sustainability across the entire lifecycle.

Real-World Applications in Automotive

a. Electric Vehicle (EV) Systems

EV manufacturers use digital twins to simulate battery performance, heat distribution, and range optimization, creating safer, more efficient vehicles.

b. Advanced Driver Assistance Systems (ADAS)

Virtual environments powered by AI-powered digital twin simulations allow engineers to test lane-keeping, emergency braking, and vision systems in various conditions.

c. Vehicle Software Updates

Over-the-air (OTA) updates are tested through digital twins before deployment, preventing software bugs or safety risks.

d. Predictive Maintenance

By analyzing sensor data, a digital twin can forecast component failures, reducing costs and unplanned downtime.

Real-World Applications in MedTech

a. Implantable and Wearable Devices

Digital twins simulate behavior under biological stress, aiding developers in refining performance and longevity for devices like pacemakers and insulin pumps.

b. Surgical Robotics and Imaging

Before testing on humans, robotic arms and diagnostic tools are validated in digital twin environments that mimic anatomical diversity and motion.

c. Personalized Medicine

Digital twin for medical devices is becoming a foundation for personalized care—tailoring treatments based on an individual’s digital health profile.

d. Design Controls and Compliance

All testing, changes, and decisions logged within the twin can be exported for regulatory submissions, fulfilling design history file (DHF) and audit requirements.

Challenges and Considerations

While digital twin technology offers substantial advantages in innovation, quality, and efficiency, implementing it effectively—especially in highly regulated sectors like automotive and MedTech—comes with real-world challenges. These obstacles must be addressed proactively to ensure a smooth and sustainable deployment.

1. Data Integration

- One of the most significant hurdles in deploying a digital twin is consolidating diverse data sources into a unified and usable format.

- Digital twins rely on simulation tools, field sensors, ERP/PLM systems, maintenance logs, and real-time operational data to function effectively.

- Data inconsistency—such as mismatched units, time lags, or missing records—can lead to inaccurate predictions and flawed simulations.

- Integrating data from legacy systems or different vendors often requires custom APIs, middleware solutions, and a clear data governance framework.

- For success, organizations must prioritize data standardization, establish metadata tagging protocols, and ensure continuous data validation.

2. System and Process Complexity

- Creating a realistic and functional digital twin requires deep cross-disciplinary collaboration.

- In automotive, it involves mechanical engineers, embedded software developers, electronics teams, and compliance officers.

- In MedTech, it requires coordination between biomedical engineers, regulatory experts, and clinical teams to simulate devices accurately under biological conditions.

- Modeling such a diverse set of parameters—from component behavior to environmental conditions and user variability—is resource-intensive. Teams must also keep the digital twin updated as the physical product evolves, which adds ongoing overhead and requires dedicated roles or departments.

3. High Upfront Costs

- The initial investment in digital twin infrastructure can be substantial, especially for small to mid-sized enterprises.

- Costs include advanced simulation platforms, IoT sensor deployment, cloud computing resources, and specialist personnel.

- Building digital twins at scale also involves training internal teams, customizing software to industry-specific needs, and maintaining compatibility with existing tools like ALM and PLM systems.

- However, these costs are often offset by long-term gains in reduced prototyping, improved product quality, faster regulatory approval, and extended product life.

4. Cybersecurity and Data Privacy

- Security is paramount when using digital twins—particularly in healthcare, where sensitive patient data may be involved.

- Digital twins in MedTech must comply with regulations such as HIPAA (U.S.), GDPR (EU), and local medical data privacy laws.

- Automotive manufacturers handling telemetry, driver behavior, or in-vehicle diagnostics must safeguard this information against breaches and misuse.

- Cybersecurity protocols must include:

- Data encryption at rest and in transit

- Role-based access control

- Audit trails for all interactions with the twin

- Regular vulnerability assessments and penetration testing

- Organizations must also consider ethical data usage, especially as digital twins are paired with AI and machine learning to make autonomous decisions.

Getting Started with Digital Twin Integration

Deploying a digital twin doesn’t require a massive transformation all at once. With the right planning, organizations can adopt the technology in phases that align with business goals and internal readiness. Here’s how to begin effectively:

1. Set Clear Objectives

Start by identifying the primary goals for using a digital twin—this could include regulatory compliance, faster product development, reduced failure rates, or enhanced lifecycle visibility. Clear KPIs will guide tool selection, team alignment, and performance evaluation.

2. Prioritize High-Impact Products

Choose a product line where a digital twin can make the biggest difference. In automotive, this could be an EV platform with complex battery management. In MedTech, it may be a device under strict clinical testing or with high customization requirements.

3. Choose Flexible, Scalable Tools

Opt for digital twin and ALM software solutions that are modular and interoperable with your existing PLM, simulation tools, and compliance platforms. This ensures future scalability and avoids data silos.

4. Build a Cross-Functional Team

Bring together stakeholders from engineering, quality, IT, and regulatory functions. Successful digital twin projects require input from all stages of the product lifecycle to ensure accuracy and usability across departments.

5. Run Pilot Projects

Start with a limited-scope deployment to validate feasibility. Monitor performance, gather feedback, and fine-tune your workflows. A successful pilot builds internal confidence and provides a template for scaling across the organization.

Future Outlook

As industries advance deeper into digital transformation, digital twins are rapidly transitioning from experimental tools to mission-critical assets. What began as isolated simulation models will evolve into real-time, intelligent ecosystems that connect engineering, operations, and business strategy. Below are the key trends shaping the future of digital twin adoption across regulated and innovation-intensive sectors.

1. Digital Twin Ecosystems for Collaborative Engineering

- The future of digital twins lies not in isolated silos but in interconnected ecosystems where OEMs, suppliers, customers, and even regulators work collaboratively.

- In the automotive industry, vehicle manufacturers will maintain persistent digital twins that evolve with every software update, aftermarket modification, or compliance requirement.

- In MedTech, shared digital twins of devices and systems will be co-developed by R&D teams, clinical researchers, and regulators—ensuring that product safety and performance are continuously monitored and improved.

- Such ecosystems enable cross-organizational innovation, faster response to field issues, and real-time feedback loops between the physical and digital worlds.

2. AI-Powered Optimization and Autonomous Decision-Making

- The next generation of digital twins will be AI-enhanced, capable of learning from live data and making decisions without human intervention.

- In automotive use cases, this could mean autonomous tuning of braking or suspension systems based on environmental data gathered from other vehicles in the field.

- In MedTech, digital twins could adjust insulin pump dosages or neurostimulator behavior based on ongoing patient vitals—within predefined safety parameters.

- This shift toward self-optimizing digital twins opens the door to predictive intelligence, adaptive design, and resilient manufacturing, dramatically improving agility and efficiency.

3. Widespread Use in Sustainable Manufacturing

- Digital twins will play a crucial role in the global movement toward sustainable manufacturing and the circular economy.

- They will help engineers assess the lifecycle impact of materials and design choices, optimizing for carbon footprint, energy consumption, and recyclability from the outset.

- Manufacturers will use twins to simulate end-of-life scenarios, reuse strategies, and remanufacturing workflows, thereby extending product life and reducing environmental impact.

- As regulatory pressure and consumer demand for sustainability increase, digital twins will become key tools for meeting ESG goals and reporting requirements.

4. Convergence with Smart Factory Automation Platforms

- Digital twins are converging with smart factory technologies such as Industrial IoT (IIoT), robotic process automation (RPA), and edge computing—creating a closed-loop manufacturing environment.

- Real-time shop floor data will feed back into the twin, which in turn will instruct robots, update software, or trigger maintenance autonomously.

- This deep integration will give rise to hyperconnected factories that self-optimize for quality, cost, and throughput without constant human oversight.

- The synergy between digital twin in product development and smart factory automation will revolutionize how products are designed, built, tested, and refined across their lifespans.

Closing Thoughts

As digital twins mature and scale, they will become indispensable for organizations pursuing:

- Faster product cycles

- Risk-aware innovation

- Precision engineering

- Regulatory resilience

- Sustainable competitiveness

In the coming years, digital twins will not just support product development—they will shape strategy, govern operations, and empower decision-making at every level of the enterprise.

Conclusion

Digital twin technology is redefining how we approach product design, validation, and maintenance—especially in automotive and medical device sectors. With its ability to reduce time, improve quality, and ensure compliance, it’s fast becoming essential to the future of engineering.

Companies that embrace the digital thread, align it with product lifecycle management, and invest in scalable digital twin simulation will lead the next era of intelligent manufacturing.